Pacific Faculty, Staff, Students Rise to Meet the Challenges Posed by COVID-19

This is Pacific University’s Rosie the Riveter moment.

Like the near-mythic World War II homefront hero, Pacific’s staff, students and faculty members are responding to the threat of pandemic with a variety of practical solutions: making facemasks, face-shield parts and hand sanitizer for front-line health responders. They represent the university’s flowering of creativity as it rises to meet a once-a-century health crisis.

Hand Sanitizer

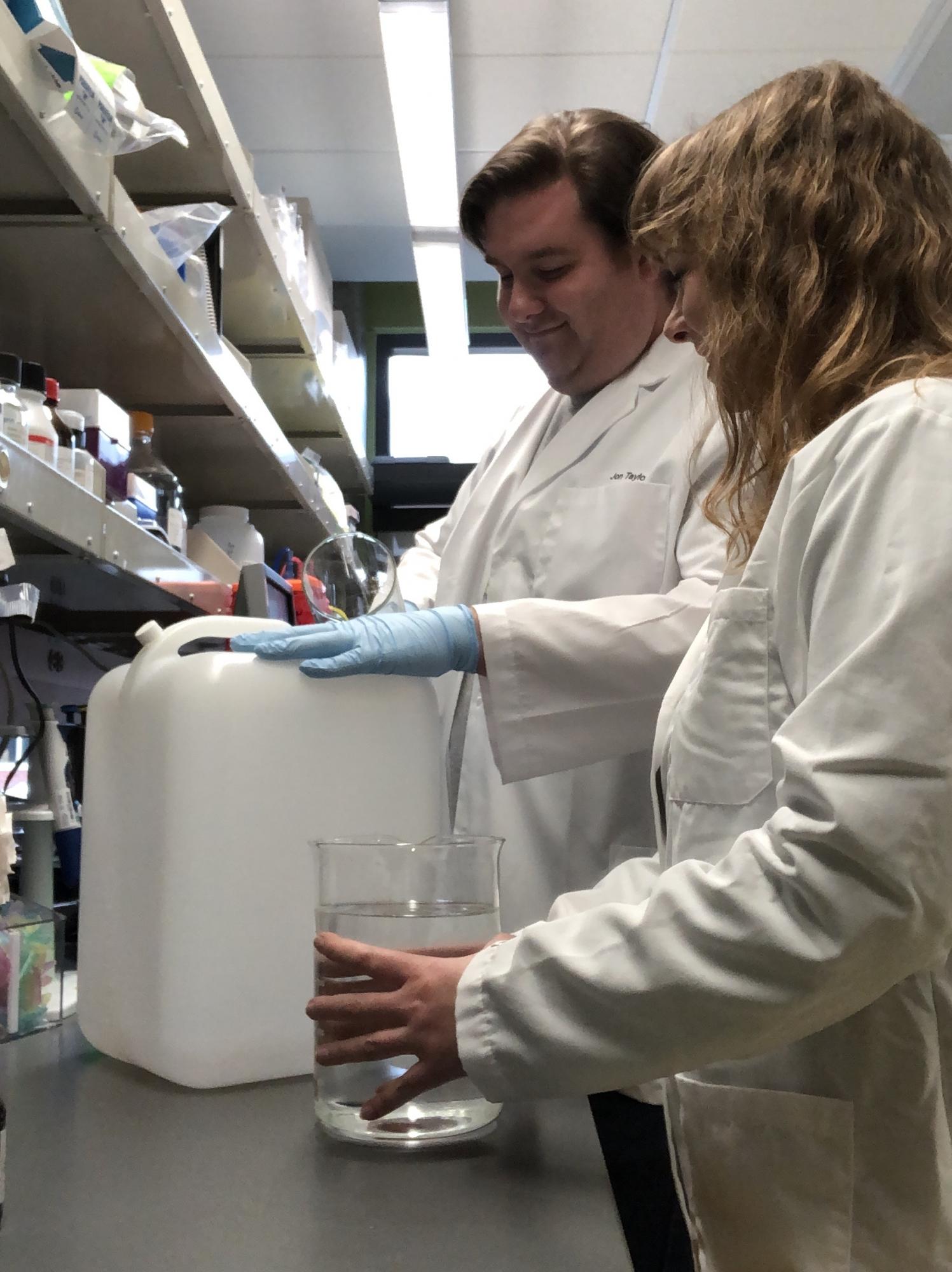

Back before the general quarantine was in place and students were still on campus, Jonathan Taylor, a research assistant in the School of Pharmacy lab, and Janelle Gomora, the lab’s coordinator, noticed that anxious shoppers had depleted supplies of hand sanitizer.

Back before the general quarantine was in place and students were still on campus, Jonathan Taylor, a research assistant in the School of Pharmacy lab, and Janelle Gomora, the lab’s coordinator, noticed that anxious shoppers had depleted supplies of hand sanitizer.

“We can do something about that,” Taylor thought.

Making hand sanitizer isn’t rocket science. The World Health Organization has published a guide to local production that is being followed by distilleries, laboratories and others who are practiced in using chemistry to produce products. It calls for ethanol, hydrogen peroxide, glycerol, distilled water and isopropyl alcohol.

Taylor and Gomora asked their bosses at the School of Pharmacy if they could make a batch of hand sanitizer for use on Pacific’s campus. The bosses said go ahead.

Then came the extreme quarantining measures that led the university to shift classes online, encourage students to go home, and shutter campus buildings. Taylor and Gomora had 10 liters of hand sanitizer with nowhere to go.

This week, the bottles of hand sanitizer, emblazoned with a Pacific University logo, will be given to Virginia Garcia Memorial Health Clinics, with which Pacific has a close working relationship.

It feels good, the two noted. And, said Taylor, “We can make more.”

Medical Facemasks

Every theater department should have a costume shop, where stage-appropriate clothing and accessories can be produced. In the time of COVID-19, Melissa Heller, Pacific University’s costume shop manager, has launched an initiative to make medical masks, which frontline healthcare workers need.

She and her students in the Theatre & Dance Department have produced an 11:24 video tutorial on making the masks. The video features Heller explaining what’s needed and showing how to sew the masks and package them for distribution.

She and her students in the Theatre & Dance Department have produced an 11:24 video tutorial on making the masks. The video features Heller explaining what’s needed and showing how to sew the masks and package them for distribution.

She makes it look easy.

“You can participate in this program if you have basic sewing knowledge, a machine, and are not currently showing signs of COVID-19, or sheltering with anybody who is,” she explains at the outset. Then she cuts, irons, pins, stitches to create a pleated cotton mask that can be stretched over the ears and worn over the mouth.

“Please join our efforts to produce this lifesaving device,” she says.

Heller says some student workers will continue to make masks with supplies kept by the costume shop, and that another is sourcing materials for more.

YouTube and other platforms are bursting with mask-making guides, and major manufacturers like Hanes and Fanatics, which typically makes baseball uniforms, have pivoted to contribute to the effort. Pacific’s effort is among the forefront in this part of Oregon. Heller invites students to participate, right down to steering them to the Tran Library to pick up zippable plastic bags and drop off their completed masks.

She advises maskmakers to ship the finished masks directly to healthcare workers who have applied to get them via mask-match.com. She's also working directly with Tuality Healthcare to make and deliver masks directly.

Faceshield Components

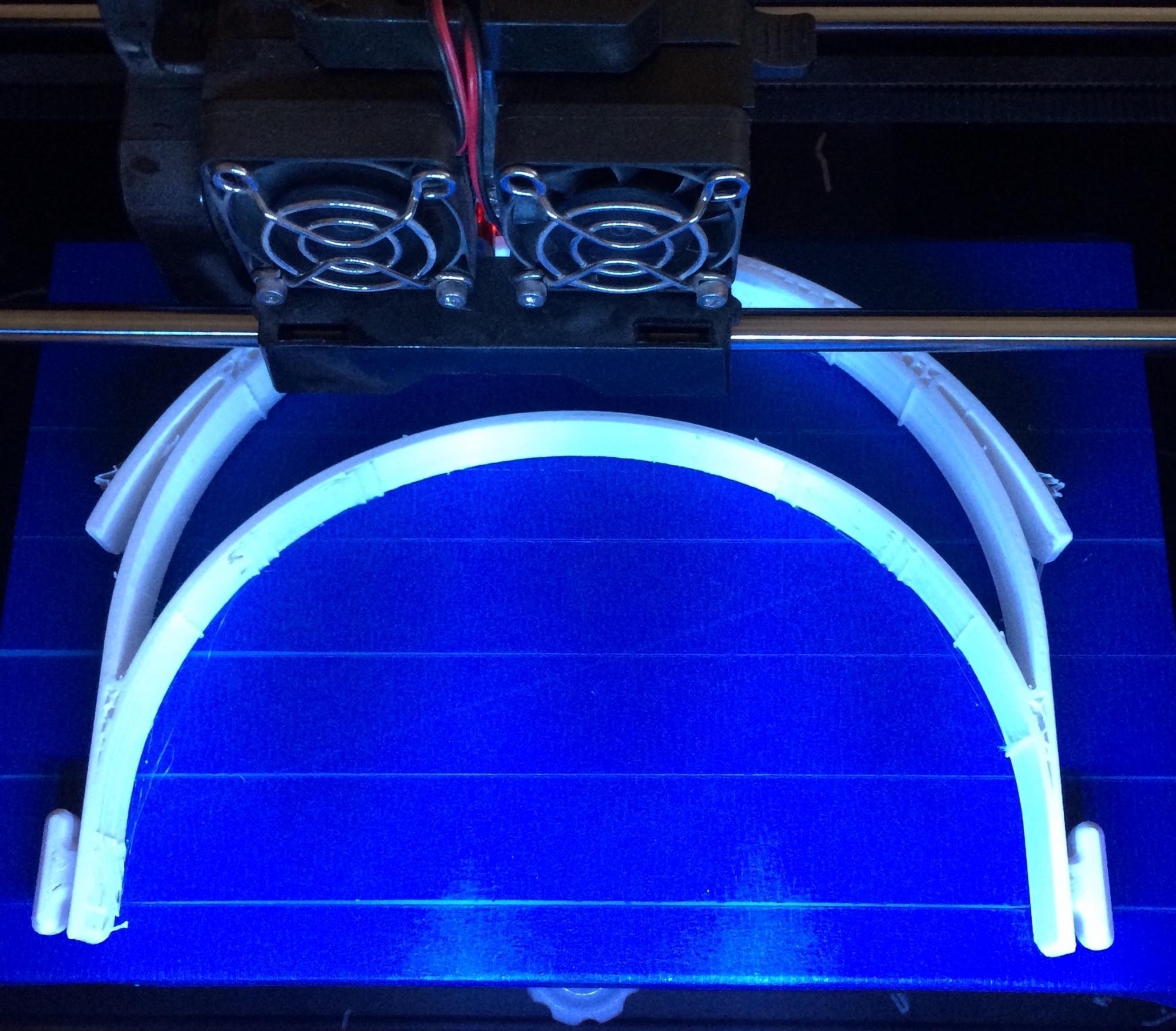

Tyler Brumfield, a professor in Pacific’s Art Department, is printing components for face shields in the makerspace shop in Tabitha Brown Hall. Over the weekend of March 29, he had used a 3-D printer to produce 12 of the headbands to which faceshields are attached.

Tyler Brumfield, a professor in Pacific’s Art Department, is printing components for face shields in the makerspace shop in Tabitha Brown Hall. Over the weekend of March 29, he had used a 3-D printer to produce 12 of the headbands to which faceshields are attached.

“I joined a group of folks organized by the Portland 3D Printing Lab to print COVID-19 medical supplies from open source files,” he said. People all over the Portland metro area are printing pieces. Some others are laser-cutting the face shield itself.

“There are a few drop off locations in Beaverton,” he said by email. “I'll drive them out once I have a significant number of them.”

It’s a way to contribute to a larger social need, he said. “So glad to be able to participate in efforts to protect healthcare workers!” he wrote.